- Why is electrical testing important?

Electrical testing is important because it helps to prevent electrical hazards, such as fire and shock, in the workplace. By ensuring that all electrical equipment is in good working order, businesses can reduce the risk of accidents and increase the reliability and efficiency of their electrical systems.

- What are the common types of electrical tests performed on commercial equipment?

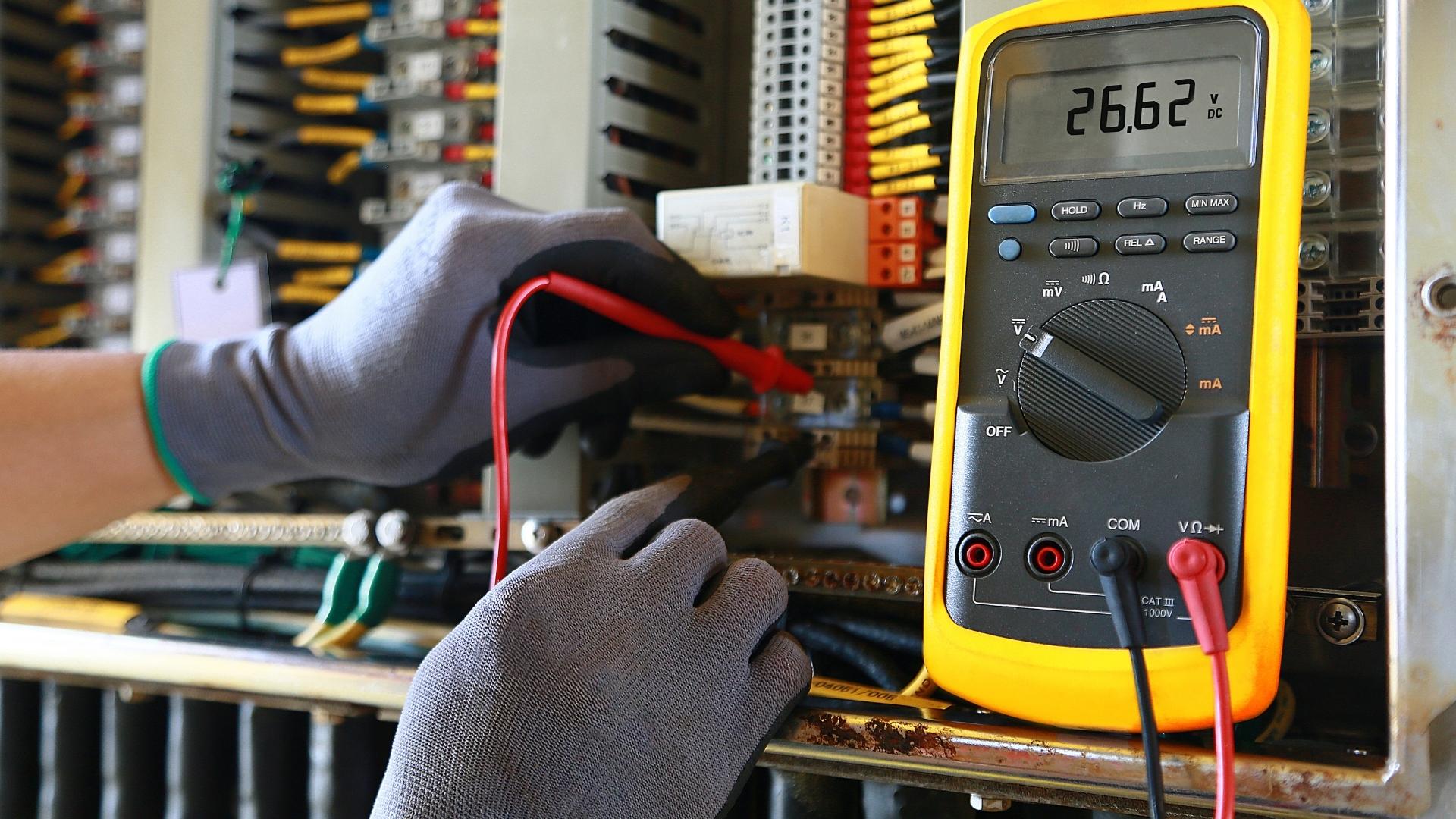

Common types of electrical tests include insulation resistance testing, earth continuity testing, voltage testing, current testing, and functional testing. These tests are designed to assess the performance and safety of electrical systems and components.

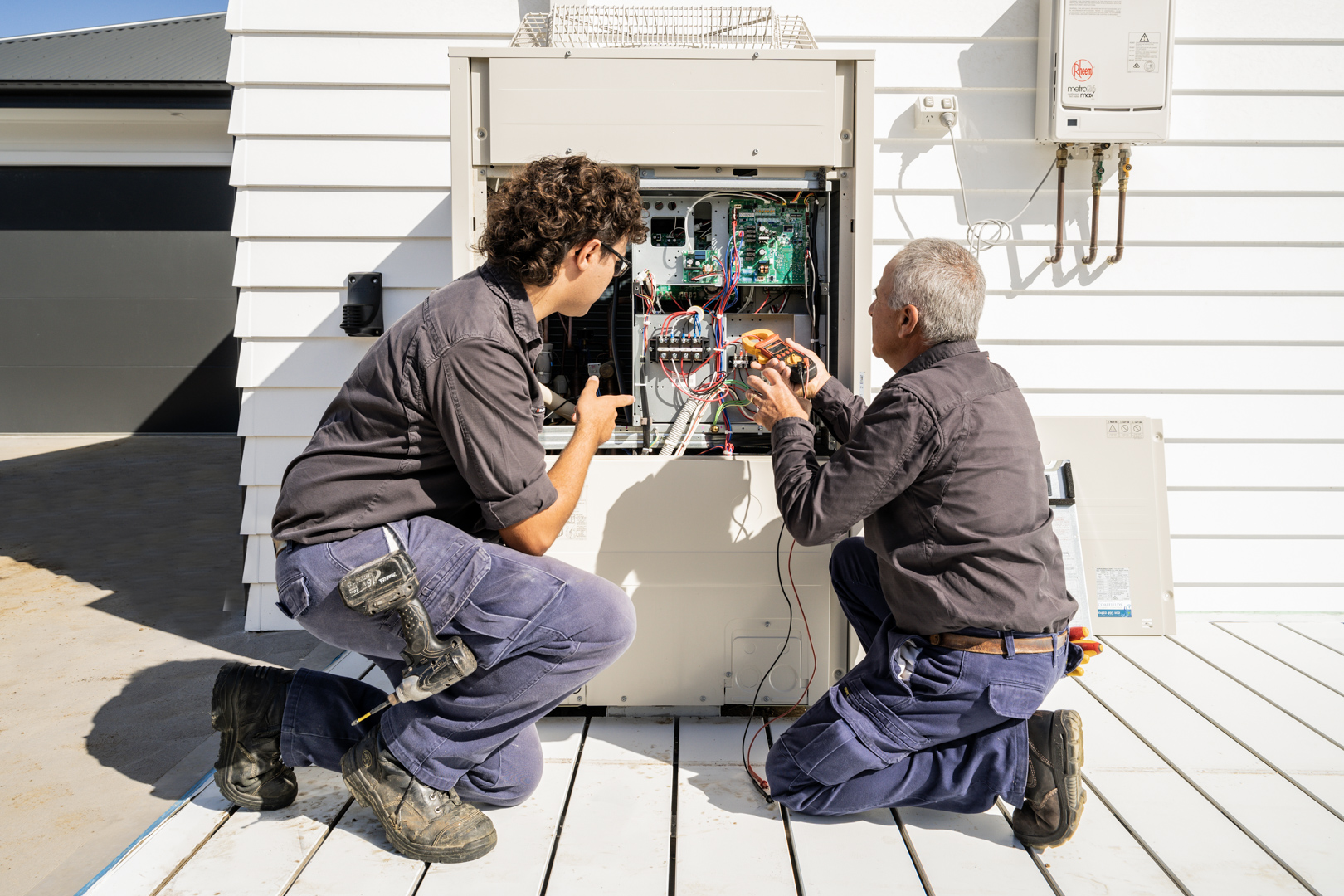

- Who should perform electrical testing on commercial equipment?

Electrical testing should be performed by a qualified and experienced electrician or electrical testing specialist. These professionals have the necessary training, skills, and equipment to carry out electrical tests safely and accurately.

- What is testing and tagging in Australia?

Testing and tagging is a process of checking electrical equipment and appliances to ensure they are safe to use and meet the Australian electrical safety standards. The equipment is tested and then tagged with a label indicating its status and the date of its next test.

- Why is testing and tagging important in Australia?

It’s important in Australia to ensure the safety of workers and the public. Electrical equipment that is damaged, worn or has been repaired can pose a risk of electrical shock, fire or injury. Testing and tagging helps to identify any issues and ensure that faulty equipment is removed from service.

- What is RCD testing in Australia?

RCD (Residual Current Device) testing in Australia refers to the process of checking the operation of RCDs, which are safety devices that protect people from electric shock. RCDs work by detecting and interrupting the flow of electrical current if a fault is detected, thus reducing the risk of electrocution.

- Why is RCD testing important in Australia?

RCD testing is important in Australia as it ensures that RCDs are functioning correctly and providing the necessary protection against electrical shock. Regular testing helps to identify any faults in the RCD and ensure that it is in good working order, thus reducing the risk of accidents in the workplace.

- How often should RCDs be tested in Australia?

RCDs in Australia should be tested every three to six months to ensure that they are functioning correctly. It is also recommended to test RCDs after any electrical work has been carried out or if there has been a power outage in the area. RCD testing should be performed by a qualified electrician who has the necessary equipment and knowledge to carry out the tests safely and accurately.

Electrical Testing For Defects

The test and tagging process ensures the safety of people in the workplace by checking electrical equipment and appliances in a scheduled time period. Electrical tagging and testing your equipment combines 2 parts. Visually assessing the appliance for defects and damage and then testing it with an appliance tester to ensure correct electrical integrity.